Industrial Spherical Bridge Bearing

Product Details:

- Color Silver or customised

- Usage Bridge, Highway, Road, Bridge Road Highway construction

- Product Type Spherical Bearings

- Weight 120-1000 Kilograms (kg)

- Structure Standard Structure

- Size 40*35/50*35/65*35/70*35/75*35/90*35mm

- Lubrication Type Other

- Click to View more

Industrial Spherical Bridge Bearing Price And Quantity

- 50.00 - 100.00 USD ($)/Piece

- 10 Piece

Industrial Spherical Bridge Bearing Product Specifications

- 120-1000 Kilograms (kg)

- Stainless Steel

- Other

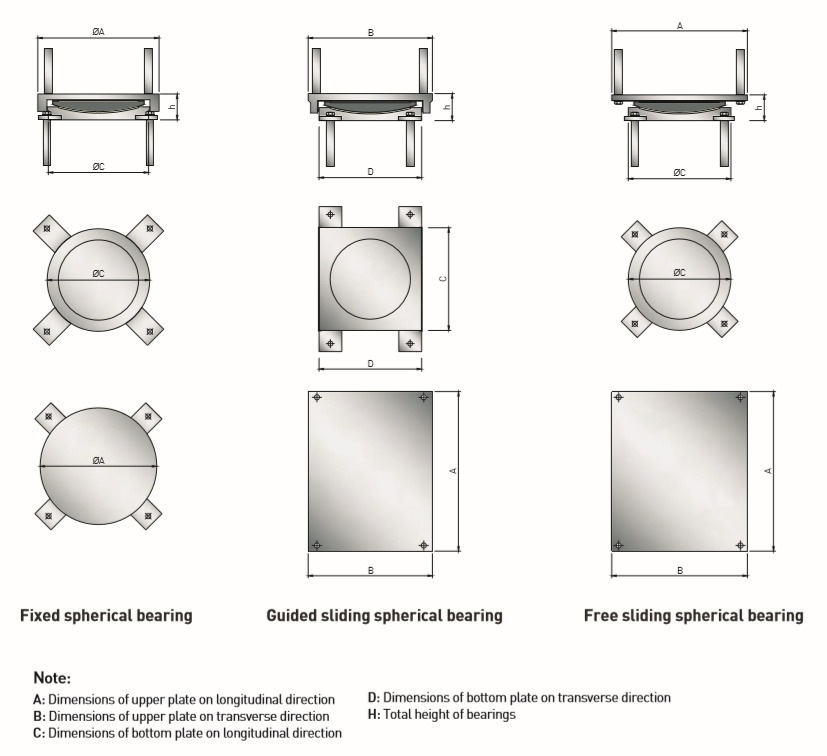

- Free sliding, Guide Sliding and Fix

- Spherical Bearings

- Bridge, Highway, Road, Bridge Road Highway construction

- 40*35/50*35/65*35/70*35/75*35/90*35mm

- Standard Structure

- Silver or customised

- 1 year

Industrial Spherical Bridge Bearing Trade Information

- Vietnam

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 1000 Piece Per Month

- 45-60 Months

- Yes

- Within a certain price range free samples are available

- Wooden box or Pallet.

- Western Europe North America Eastern Europe Middle East Africa Australia Central America South America Asia

- All India

- ISO, ASTM

Product Description

We offer Industrial Spherical Bearing that is used in the railways. The product is designed with latest intelligent engineering and high grade material by the experienced manufacturers. We are the leading manufacturer and supplier of top quality components as a perfect replaceable option. The Industrial Spherical Bearing is available at a very competitive price.

Product description :

VHC spherical Bearings manufactured by Vinh Hung Investment and Production Company Limited (Vinh Hung IP) are capable of with standing the high loads and movements suitable for structures requiring the rotary angle equal or bigger than 0.015 rad in all directions. VHC spherical bearings are designed and manufactured according to current standards such as: TCVN 11823, AASHTO LRFD, ASTM D5977, EN 1337, ...

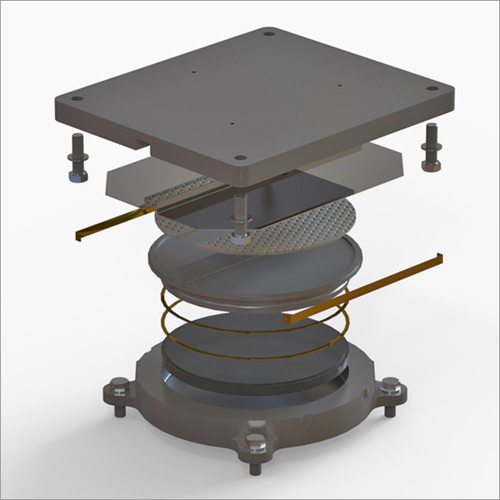

VHC spherical bearings possess a concave lower part (6) which has a PTFE sliding sheet (4) on it is upper curved surface. A convex calotte (5) is placed on top of this, which, thanks to it is polished hard-chromium plated surface, can slide within the lower part with low friction, thus facilitating rotations about every axis. A second sliding sheet of PTFE (4) is recessed into the upper surface of the calotte. Together with the top plate (2) above it, this accommodates longitudinal and/or transverse sliding movements of the superstructure, if required. To reduce sliding resistance to a minimum, the lower surface of the top plate features a polished stainless steel sheet. In the case of bearings which should allow movement along one axis only, the direction of movement is controlled by guide bars (3). In the case of fixed bearings, the top plate do not have stainless steel sheet. The bearing is connected to the superstructure and the substructure by means of anchor dowels (1) or threaded sleeves (depending on design), or alternatively by means of separate anchor plates with shear studs.

To ensure the long-life durability, VHC spherical bearings are protected against corrosion by the following methods: coating with two-component epoxy, PU-based painting (Polyurethane), hot dip galvanization according to ASTM A123 standards and especially the Al Mg spray coating method (at the ratio of 5% Al and95% Mg) which ensure the anti-corrosion durability of upto 100 years, this method is proved by the salt-spraying test in 6000 hours (8-hour dry-wet cycle) according to ASTM B117

Other Products in 'Bearing Part' category

|

VINH HUNG TRADING, CONSULTING AND CONSTRUCTION JSC

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese